Transport casks

Stringent specifications for the casks

Radioactive waste is packed in different types of casks. These can be made of steel, concrete or even sheet metal.

Medium level waste has to be shielded and is cast into casks of concrete or steel at the nuclear power plants. It is then transported in transport casks with thick (7–20 cm) steel walls, depending on the type of waste. Low level waste does not need radiation shielding and can therefore be transported in normal containers made of sheet metal.

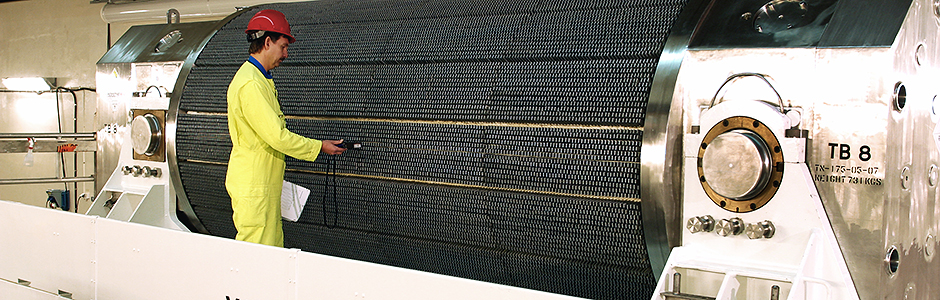

Spent nuclear fuel is highly radioactive. It therefore has to be shielded while it is being handled, transported or stored. Before transport the fuel is moved under water into a transport cask with a steel wall that is about 30 centimeter thick. This shields against radiation and at the same time protects the fuel element. The external surfaces of the casks are equipped with cooling flanges of copper to conduct the heat away from the fuel.

International standards

The casks are constructed to withstand much rougher treatment than can reasonably be expected during transport. They have to comply with international standards, which include being able to withstand a drop of nine metres on to a totally unyielding surface, more than 30 minutes in a fire at over 800 °C, and external pressure corresponding to immersion at a depth of 200 metres under water without any leakage occurring.

The casks comply with these requirements with very broad margins. For instance they can withstand pressure corresponding to immersion at a depth of more than 4,000 metres under water.