SKB to weld canisters for world’s first final repository

Swedish Nuclear Fuel and Waste Management Co., SKB, is to weld canisters for the Finnish final repository for spent nuclear fuel. An agreement has been concluded between SKB and its Finnish counterpart, Posiva Oy, under which SKB will weld the bases of the Finnish canisters. Work will start in 2025, and will be performed in SKB’s canister laboratory in Oskarshamn.

Magnus Holmqvist, CEO of SKB International AB

– We’ve been offering our services to sister organisations all over the world for many years. As Finland is using the final repository method developed by SKB, KBS-3, we’ve been sharing knowledge and experience with each other for a long time. This agreement gives us the opportunity to deliver a finished product. It will give us further experience in exporting the technology, knowledge and experience that SKB has developed over the past 40 years, says Magnus Holmqvist, CEO of SKB International AB.

Posiva recently completed its final repository in Onkalo and is awaiting a licence from its regulatory authority to start operating the facility. The company needs to weld bases for the canisters in which the spent nuclear fuel will be stored, so it turned to its colleagues in Sweden.

– This agreement sees us taking another step towards putting the world’s first final repository for spent nuclear fuel into operation. To be time-efficient, we chose to award the contract to SKB, which has successfully welded many canister bases. This means that we avoid additional costs, and we know that SKB will deliver high-quality work, says Ilkka Poikolainen, CEO of Posiva.

The agreement has been signed for five years, with an option for two more years. The work, which will be performed at the Canister Laboratory in Oskarshamn, is planned to start in 2025. The agreement covers the welding of approximately 160 canisters in total.

Finland’s final repository will be built using the final repository solution for spent nuclear fuel that was developed in full by SKB in Sweden. The method is called KBS-3 and is based on three protective barriers: the copper canister that encloses the spent nuclear fuel, the clay buffer that surrounds the canister and protects against minor movements in the rock, and the Swedish bedrock to provide the outermost barrier. SKB and Posiva have been collaborating since 2001 to develop and test the method of final disposal.

SKB International

SKB International is a wholly-owned subsidiary of SKB, which provides services and expertise in the management and final disposal of nuclear waste and spent nuclear fuel based on the technology, know-how and experience developed in SKB’s programmes over the past 40 years. SKB International operates all around the world, with assignments in countries including Japan, South Korea, Taiwan, Norway and Germany. In total, SKB international has helped around 50 organisations around the world with knowledge and guidance on the management of nuclear waste and on SKB’s work to gain local acceptance.

More about welding technology

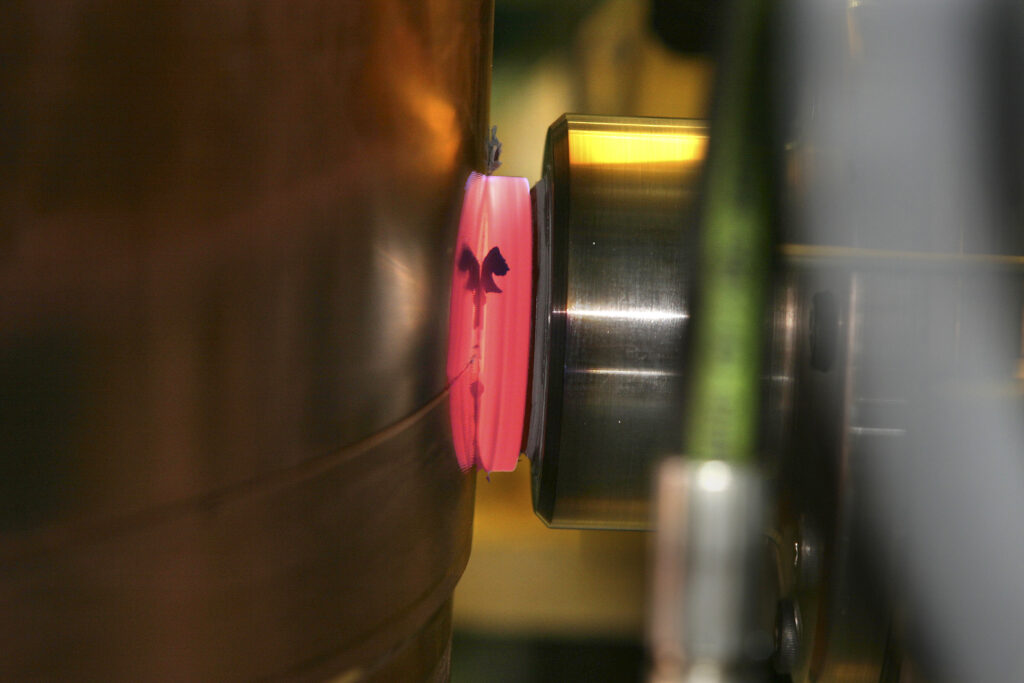

The welding method used is called friction welding, or more specifically friction stir welding, which has been specially adapted by SKB to weld copper. It is a mechanical welding technique with a rotating conical tool that is pressed into the joint between the parts to be welded. The material around the tool is heated by the friction and becomes soft. As the tool rotates, the copper material is stirred on both sides of the joint and binds the two metal parts together to form a homogeneous weld joint.

Published: 16 December 2024

News

-

Technology development and optimisation for best available technology

SKB is continuously working to develop and optimise the design of all the barriers in the final repository for spent nuclear fuel, with stringent requirements for long-term safety. The development work also involves industrialising manufacturing processes as well as construction and deposition proce…Published: 23 December 2025

-

SKB signs new agreement with South Korean repository organisation

Swedish Nuclear Fuel and Waste Management Company, SKB, through its subsidiary SKB International, has signed a new Memorandum of Understanding with its counterpart in South Korea, Korea Radioactive Waste Agency (KORAD). The agreement, which is an information exchange agreement, strengthens the relat…Published: 18 November 2025

-

SKB presents new research programme

SKB has submitted its eighteenth research programme to the Swedish Radiation Safety Authority. The report provides a comprehensive overview of progress made and outlines SKB’s future research direction. Every three years, SKB presents a Research, Development and Demonstration programme for the manag…Published: 6 October 2025

-

SKB signs collaboration agreement for the Spent Fuel Repository

SKB has signed a collaboration agreement with Implenia for the construction of the Spent Fuel Repository’s hard rock facility in Forsmark. The assignment includes access routes down to a repository level of 500 metres and the first parts of the final repository.Published: 18 June 2025

-

Drones streamline inspections and patrols at SFR

At the Final Repository for Short-Lived Radioactive Waste, SFR, in Forsmark, the maintenance team has invested in a drone to improve the work environment and streamline their work. The investment has already paid for itself during the first few months of the year through more efficient inspections a…Published: 17 June 2025

Published: 16 December 2024