Multipurpose test facility

Multipurpose test facility

In the Multipurpose test facility methods are developed and tested for installing the bentonite clay that will be used in the Spent Fuel Repository – both as buffer material around the canisters and as backfill in the deposition tunnels.

In the future repository, one canister is planned to be deposited per day. Around each canister, a buffer of bentonite clay will be installed, while six meters of the deposition tunnel will be filled with backfill material.

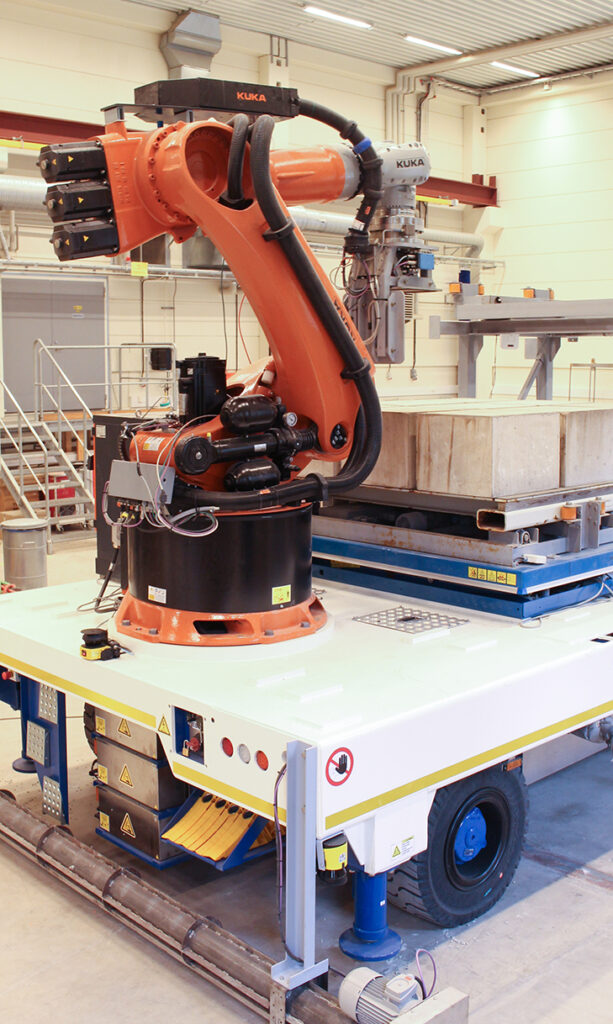

An industrial robot equipped with special tools for gripping and stacking bentonite blocks.

Bentonite blocks

For SKB, it is crucial to develop production and control methods that are repeatable under industrial conditions and maintain sufficiently high quality ahead of the operation of the Spent Fuel Repository. Adjacent to the Äspö Laboratory is SKB’s Multi purpose test facility, where activities mainly focus on ensuring that the installation methods for buffer and backfill function under all expected conditions.

Tunnel models and test equipment

In the Multipurpose test facility, experiments and trials are conducted with bentonite clay in various forms. Equipment is available for mixing bentonite material, producing pellets, and tools for lifting buffer rings. A specially adapted stacking robot is used for stacking bentonite blocks.

The 450-square-meter hall also contains full-scale and half-scale models of deposition tunnels, where installation equipment can be tested under controlled conditions. In the floor, there are two holes that simulate the deposition holes in the repository. These allow testing of the deposition process and examination of how the bentonite reacts to different water flows.

Trials have also been carried out deep underground in the Äspö Laboratory to test the equipment under repository-like conditions.

Last review: August 18, 2025

Last review: August 18, 2025