Technology development and optimisation for best available technology

SKB is continuously working to develop and optimise the design of all the barriers in the final repository for spent nuclear fuel, with stringent requirements for long-term safety.

The development work also involves industrialising manufacturing processes as well as construction and deposition processes. Among other things, we must enable large-scale production of 6,000 canisters. What kinds of optimisations are being made, and why are they needed when the method has already been approved? We asked Susanne Andersson, head of Engineering at SKB:

Susanne Andersson, head of Engineering Photo Mikael Wallerstedt

– It’s about the fact that we have researched and developed the final repository method, KBS-3, from the ground up, it has been reviewed and approved, and we are now about to start applying it. We will manufacture all the components, build the facilities, and commission them. Since there is not just one way to, for example, build a tunnel or manufacture canisters and bentonite blocks, we have been working for several years on optimising the entire concept.

Can you give us some examples?

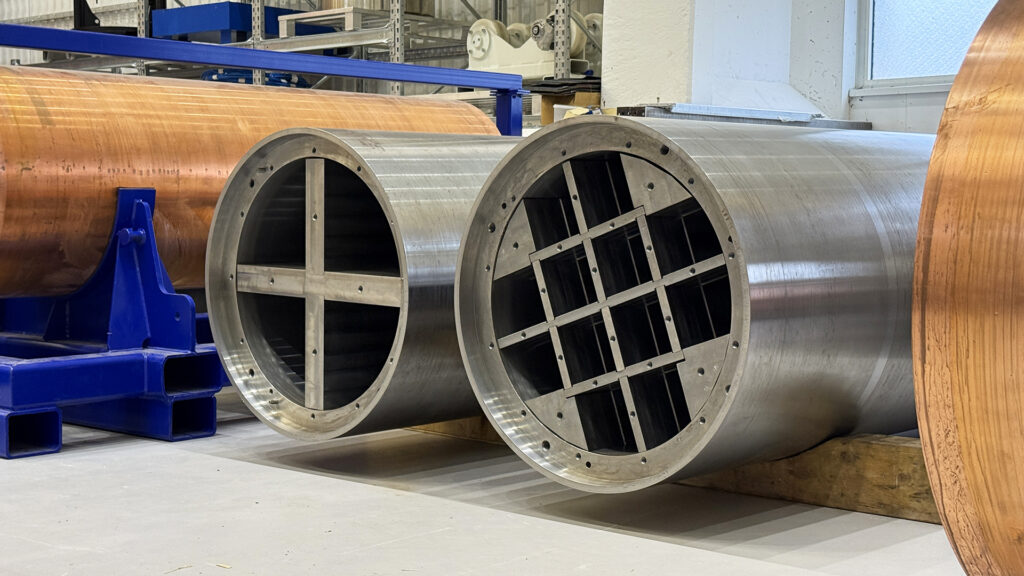

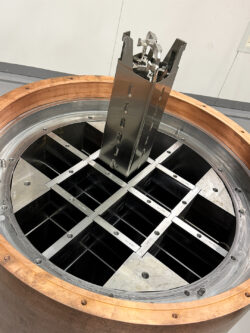

– One of the major examples of optimisation is that we have decided to manufacture the canister insert from hot-formed carbon steel components instead of cast iron. We can use both materials, but after several years of development we see that using a carbon steel insert provides a more robust, simpler, and more reliable manufacturing process. We have collaborated with potential insert manufacturers and carried out trial production of a number of inserts with good results.

Fuel element in the new steel insert.

– This has resulted in an insert that is assessed to be better and ready for production. We have now submitted supplementary documentation to the Swedish Radiation Safety Authority (SSM) for the new insert, so that they can continue their review of the preliminary safety analysis report for the Spent Fuel Repository, in which the canisters are included as a component.

– Other examples include the backfilling of the tunnel system and alternative manufacturing methods for copper components – all while maintaining the same requirements but using different approaches for practical implementation.

How long will the technology development work continue?

– We have a number of technology choices to make over the coming years in order to industrialise the entire final repository concept, so that both the manufacturing of all components and the operation of the facilities can be carried out efficiently. But the development work will not end there; it will continue throughout the entire construction and operational period, that is, all the way into the 2080s when the Spent Fuel Repository is to be sealed.

Published: 23 December 2025

News

-

SKB signs new agreement with South Korean repository organisation

Swedish Nuclear Fuel and Waste Management Company, SKB, through its subsidiary SKB International, has signed a new Memorandum of Understanding with its counterpart in South Korea, Korea Radioactive Waste Agency (KORAD). The agreement, which is an information exchange agreement, strengthens the relat…Published: 18 November 2025

-

SKB presents new research programme

SKB has submitted its eighteenth research programme to the Swedish Radiation Safety Authority. The report provides a comprehensive overview of progress made and outlines SKB’s future research direction. Every three years, SKB presents a Research, Development and Demonstration programme for the manag…Published: 6 October 2025

-

SKB signs collaboration agreement for the Spent Fuel Repository

SKB has signed a collaboration agreement with Implenia for the construction of the Spent Fuel Repository’s hard rock facility in Forsmark. The assignment includes access routes down to a repository level of 500 metres and the first parts of the final repository.Published: 18 June 2025

-

Drones streamline inspections and patrols at SFR

At the Final Repository for Short-Lived Radioactive Waste, SFR, in Forsmark, the maintenance team has invested in a drone to improve the work environment and streamline their work. The investment has already paid for itself during the first few months of the year through more efficient inspections a…Published: 17 June 2025

-

Blasting starts on the SFR extension in Forsmark

Work to extend SFR, the final repository for short-lived radioactive waste, began today with a blast 45 metres below ground. The blast marked the start of the six-year extension project.Published: 23 January 2025

Published: 23 December 2025