Encapsulation plant

Fuel encapsulated in copper

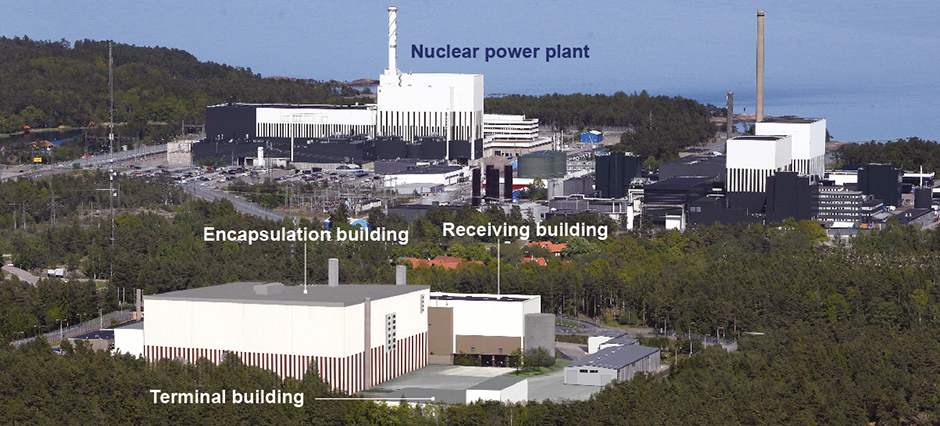

Before the spent nuclear fuel is transported to the Spent Fuel Repository at Forsmark for final disposal it will be encapsulated in copper and steel. This is planned to take place in an encapsulation plant to be built next to the interim storage facility at Oskarshamn.

The plan is to build the encapsulation plant next to Clab – the interim storage facility at Oskarshamn (the whole facility will then be called Clink). In the future the fuel will still have to be kept in interim storage for some time. This will allow it to cool down and become less radioactive. Afterwards it will be placed in an insert of steel and encapsulated in copper canisters in the encapsulation plant.

The canisters will be sealed using a special friction stir welding technique and carefully inspected using non-destructive testing methods. When the process is in full swing the plant will be able to deliver about 200 full canisters per year to be transported to Forsmark and the Spent Fuel Repository on board the special transport vessel M/S Sigrid.

First stage

Encapsulation is the first stage in SKB’s method for the safe final disposal of spent nuclear fuel. The technique is unique and has been developed by SKB in collaboration with universities, HEIs and institutes of technology.

There are a number of advantages to combining the plant with the interim storage facility. The staff working at Clab have long experience of handling spent nuclear fuel. Several of the systems that already exist in the interim storage facility will also be used during encapsulation.

Government Approval and Next Steps

In January 2022, the Swedish government granted permission to build the encapsulation plant in Oskarshamn. The case was then referred back to the Swedish Radiation Safety Authority (SSM) and the Land and Environment Court (MMD), which are responsible for setting conditions for the facility under the Environmental Code and the Nuclear Activities Act. In October 2024, MMD issued an environmental permit for the plant.

To move forward, a building permit from the Municipality of Oskarshamn is also required.

SKB hopes to begin construction during the 2020s. If so, the facility could be ready for operation around the same time as the Spent Fuel Repository — approximately ten years later.

For more information about the review of the permits for the encapsulation plant, see the pages on how our applications for permits for the Spent Fuel Repository are reviewed.

In addition to the encapsulation plant SKB is also planning to build a canister factory where the copper canisters will be machined, assembled and inspected. It is also intended to site this at Oskarshamn. As there will be no spent nuclear fuel in the canister factory it is not a nuclear installation. Instead it can be viewed as a normal engineering workshop.

Last review: August 12, 2025

Last review: August 12, 2025